An ESD epoxy glass fiber is a system. It helps as a channel for electrical charge which is static. Body Voltage Generation (BVG) gathers on an individual by walking on a floor. This floor is made up of polymer. There is a calculated flow of electrical charge. The discharge supports in reduction and removal of potential. This discharge also helps in unintentional electrostatic discharging. This process can harm delicate electronic components. It can also cause damage to small electronic parts during manufacture.

There is the minutest and un-noticed electrostatic discharge. It can have adverse effects. It may affect sensitive electronic pieces of machinery. Electrostatically-sensitive microchip components are important in the production of ESD systems. Manufacturers of Printed circuit boards (PCBs) help in developing ESD control. They also support preventing programs from failing. Scrap rates are a major component of their quality control. They are also important in different manufacturing processes.

Working on ESD Flooring

An ESD floor covering consists of conductive particles. These conductive particles are submerged in its matrix. It makes the upper layer to be electrically active. Electrical current can easily travel through it. We can say that, it is like a wire. It can carry an electrical charge. This charge is transferred from one part to another.

Some insulators can’t carry current. Examples of insulators are glass, wood, and plastic. Insulation is a property of a material. Paints and polymers are devoid of this property. In some electrostatic discharge protected Areas (EPA), this flooring is very helpful. Several other ESD-protected apparatus, such as footgear, outfits, and training belts, are integrated with this floor to diminish BVG. Use this setup also to monitor proper entrapment discharge.

The Importance Of ESD Flooring

The electrostatic discharge can cause life-threatening and life-challenging issues. If there is the generation of unwanted sparks. These unwanted sparks can cause an explosion. They are explosive in flammable surroundings. We can also say that elimination and release of charge cause a little annoyance to a person. It results in a slight “shock”.

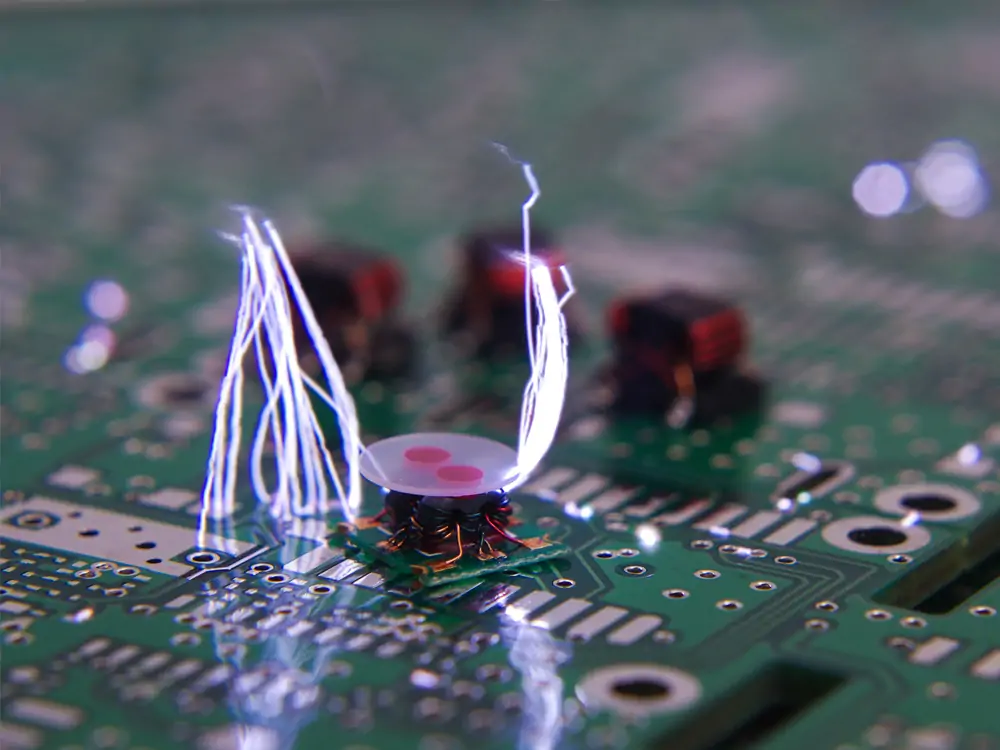

The main factor of an Electrostatic discharge system is ESD flooring. It is essential for the integrated circuit technology industry. This system is particularly accurate in circuit board integrated systems. It is useful in the production of ESD floors in buildings. We can use circuit boards for this purpose. It consists of millions of infinitesimal electric circuits. Without proper protection, it may be demolished. Or it can also be “fried” with very trivial shocks of electrostatic discharge.

The effect of electrostatic discharge on these circuit boards is noticeable. This effect is similar to a fuse in industries. It may be like a circuit breaker in houses. Such highly noticeable failures can be instantly perceived in the quality regulator procedure. We can say that these fiascoes are considered catastrophic letdowns. These catastrophes are not considerable. We can consider them the minute. Sometimes they are not noticed by the quality regulator authority. We can call these letdowns “dormant failures”. They happen very fast.

We can either use the product in the field or out of the field. In a nutshell, these catastrophes result in unpredicted, high-assurance privileges. These letdowns can smudge the producer’s reputation.

The installation and operation of an electrostatic discharge flooring system are crucial for a comprehensive ESD control system. It plays a vital role in managing the prevention database and effectively prevents such mishaps. These systems contribute to reducing failure rates and improving overall performance.

These protective Engineering Polymers suggest a complete stripe of electrostatic discharge Flooring Arrangements.

Effects of ESD system

ESD system is a common manifestation. The effects of ESD diverge. It depends on the electrical energy. The high value of the voltage of ESD may result in a lot of issues.

- It includes power-driven catastrophe

- There may be a coal dust blast

- It can cause bursts of flames

- It can cause bodily injury

- There may be a mechanical failure

- It includes include junction damage

- It results in contact confounding

- It can cause mental diffusion

Proper assembly of ESD floors is essential to minimize damage to the floors and surrounding areas. Following the obligatory guidelines ensures effective installation. Strategically placing copper tiles and bands above the epoxy resin and underneath the flooring eliminates any gaps and allows the floorboards to function optimally while reducing static interference. After correctly installing the ESD flooring, one can perform various tests to ensure its functionality.

Important parameters for testing

A person can test ESD floors for electrical reactance. He can also test it for static charge production. He can measure it with an ohmmeter. An ohmmeter measures the resistance of any circuit.

Process of testing

- Use ASTM F150 or ANSI/ESD STM 7.1 first.

- Then we use two 5-pound probes.

- We place them almost 3 to 4 feet at a distance on the floor

- Then apply 10 volts of electricity.

- We can use a voltmeter to check the static charge.

- We use ANSI/ESD STM 97.2 for measuring the static charge produced.

- Use the above steps when a person is wearing obvious footwear on the floor.

Measure of resistance

Resistance is a measure of the capability of the parquet bulk to resist. It reduces the stream of current. The unit of resistance is the ohm. Its symbol is “Ω”

Case 1

If there is low conductivity then a static charge will emancipate slightly. It shows that the floor is neutral.

Case 2

If there is high conductivity then a static charge will emancipate rapidly. It shows that the floor is electrically active. It is hazardous. We need to locate the right point between 1x10E6 and 1x10E9 Ω.

The voltage of the walking body

When a person walks on the floor a static charge gathers in his body. We can use a charge monitor to find the value of voltage. We can produce a voltage below 24 volts of static. It is very standard. It will cause even a slight shock. But if the static charge of around 3,500V. Then it will cause a strong shock to an individual. We must keep the voltage in a suitable range.