Overview Of copper clad laminate

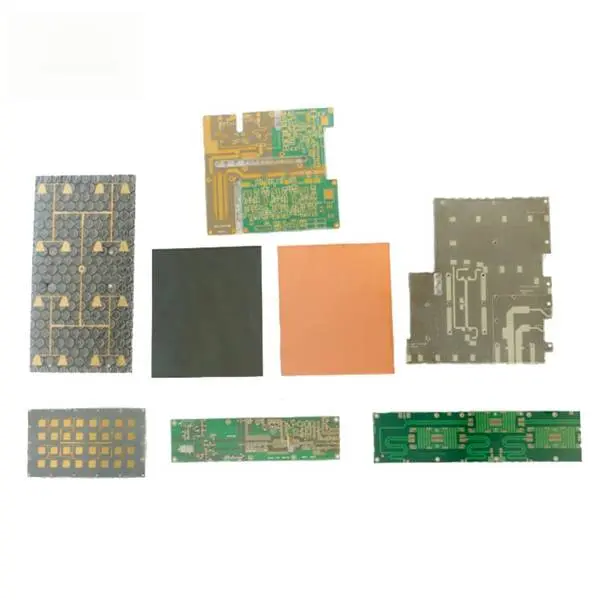

Copper clad laminates are a type of PCB substrate, characterized by their copper-covered laminated structure. We classify PCB substrates into two categories: organic and inorganic. Organic substrates comprise reinforcing materials such as glass fiber cloth, fiber paper, and glass felt. We impregnate these reinforcing materials with resin adhesive, dry them, and then apply a copper foil coating. We carry out the coating process at high temperatures and high pressure. The coating process occurs under high temperatures and pressure. This type of substrate, known as copper-clad laminate (CCL), is the main material used to make PCB.

The type of copper clad laminate sheet

Grouped by reinforcing material:

- CCL with a paper base (e.g., XPC)

- CCL with a glass fiber cloth base (e.g., FR-4, FR-5)

- Compound CCL (e.g., CEM-1, CEM-3)

- CCL with a unique material base (e.g., metal-based CCL, ceramic-based CCL, etc.)

Grouped by applied insulation resin:

- Phenolic resin CCL (e.g. XPC, XXXPC, FR-1, FR-2, etc.)

- Epoxy resin CCL (e.g. FR-3)

- Polyester resin CCL

Grouped by performance:

- General performance CCL CCL with high heat resistance

- CCL with low dielectric constant

- CCL with low CTE (Coefficient of Thermal Expansion)

Grouped by mechanical rigidity:

- high rigidity CCL

- flexible copper clad laminate

These are normal way of categorizing it. In fact, we can provide almost all copper-clad laminates on the market. If the laminated sheet you need is not specified above, please get in touch with us directly. Our sales team will respond to messages on time. And give a quotation for the CCL you need.

The similarities and differences between CCL and PCB.

A copper-clad laminate is a substrate that has copper foil coating on one or both sides.

It is made by laminating materials like glass fiber cloth, paper, or plastic with copper foil.

In PCB manufacturing, it is used to create circuit connections and provide electrical and mechanical support.CCL and PCB have distinct roles in the PCB manufacturing process, with the former allowing customization of copper foil thickness and quality for diverse applications.

Reasons for choosing our copper clad laminate

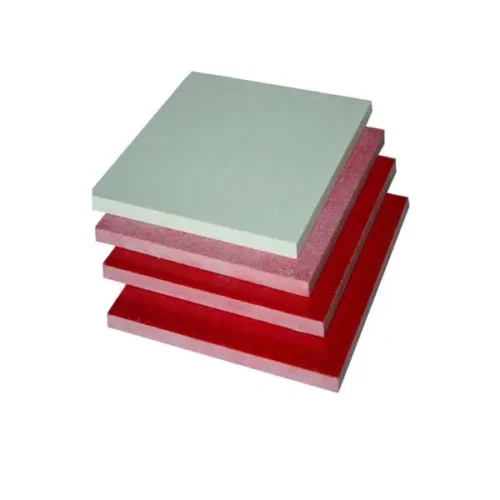

- Flat and smooth in appearance

- Length, width, diagonal deviation and warpage in tolerance

- Great electric, physical, and chemical performance

- Applies IPC-4101C as a manufacturing standard and uses IPC-TM-650 for CCL